What is a Plc? It is an electronic device used in industrial automation systems, designed to control production lines, machines, or systems. These systems have a programmable structure and can also be adapted to different processes.

What is a Plc? This system, which provides control of electronic devices in industrial environments, has a structure that is resistant to harsh conditions. Another feature of the system is its programmability to automate processes.

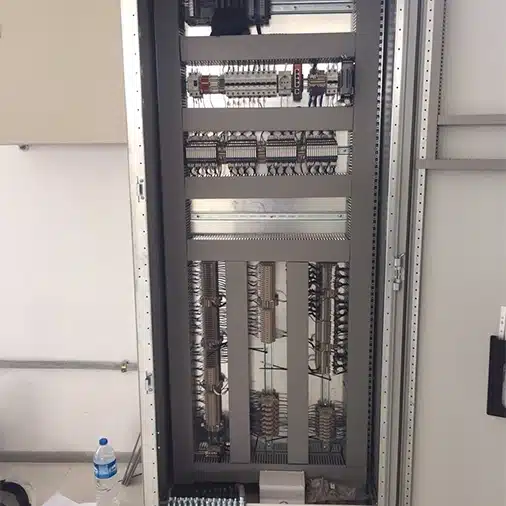

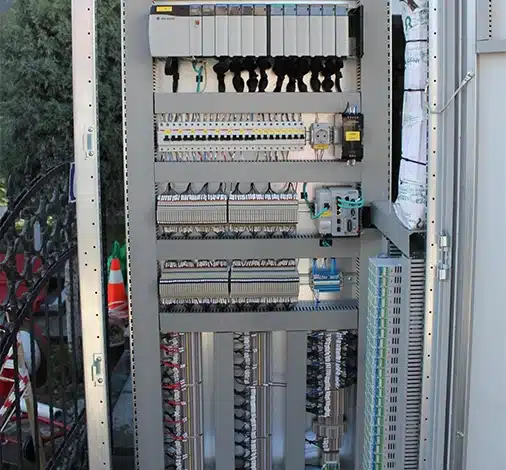

What is a Plc Center?

The abbreviation Plc stands for “programmable logic controller.” It is an electronic device used in industrial automation systems.

The center of the system is the structure where the control and monitoring tasks of the system are carried out and managed. In this center, multiple systems are operated simultaneously while data is collected and analyzed. The most important advantage of PLC centers is that they increase efficiency and make processes safer, especially in large-scale production facilities or complex industrial processes.

Components of the system’s center:

- Main PLC Control Unit

This unit is considered the heart of the center. It functions primarily and controls data from other systems. - Distributed PLCs

In this component, the units of the system are specialized for a specific area or task. For example, control devices divided into different sections of a production line can be given. - Data Communication Network

It is the network infrastructure that enables communication between programmable logic controllers. - SCADA or HMI Systems

The PLC center is integrated with these two systems. The benefits provided to users by this system include monitoring processes in real-time, changing parameters, and viewing error situations. - Data Storage and Analysis Systems

Data obtained from the system is stored and used for performance analysis, maintenance planning, and fault diagnostics.

The advantages provided by the PLC center are centralized management, facilitating the management of systems, quickly detecting errors, being expandable (i.e., allowing PLC units to be easily added or restructured), and enabling remote monitoring and control.

What is a Plc, and What Does It Do?

A PLC is designed to control machines or systems used in production lines, and the basic features of this system are its programmability, its design to operate even under challenging industrial conditions, and its provision of real-time control.

These electronic devices, which are part of industrial automation systems, are used for the following purposes:

The answer to the question “What does a PLC do?” is as follows: Plc programs control parameters such as temperature, pressure, and speed. For example, it measures the temperature in a chemical plant or adjusts the speed of a motor.

It ensures the system operates according to a logical control rule. For example, when a tank is filled to a certain level, it shuts off the pumps.

It ensures processes operate at specific intervals or sequentially. It does this through timers and counters. For example, ensuring products in packaging machines are packaged with correct timing.

A PLC collects data from sensors it is connected to and analyzes it or transfers it to SCADA/HMI systems. This data is used to optimize processes.

The system has a safety control feature. It automates safety procedures in industrial processes. For example, it shuts down machines in emergencies. This is a very important factor for safety.

PLCs are used in modern industry and are one of the fundamental components of automation.

Plc Application Areas

Plc application areas are quite extensive. Examples of commonly used areas include industrial automation systems, the energy sector, transportation, food processing, the chemical and pharmaceutical industry, and water and wastewater management.

In industrial automation systems, it automates processes such as assembly lines, controls packaging systems, and ensures robots in factories work synchronously.

In the food and beverage industry, it controls processes such as filling and packaging, optimizes temperature and humidity levels, and ensures the mixing of different components.

In energy and power systems, especially in electrical networks, it plays a critical role. It ensures generators work efficiently, regulates electricity production, plays a role in grid management, optimizes energy distribution and load balancing processes, and detects faults.

In water and wastewater management, it operates and stops water pumping systems, controls water levels in tanks, monitors pipeline pressure, and manages the filtering and chemical processes required for water purification.

In the oil and gas industry, it ensures the transportation of oil and gas through pipelines, controls refinery processes, detects potential leaks in pipelines, and takes preventive measures.

PLCs, which are used in various fields, play a critical role in many sectors, from production to infrastructure.

You can contact Mega Industry to get detailed information about PLC systems, their usage areas and features.