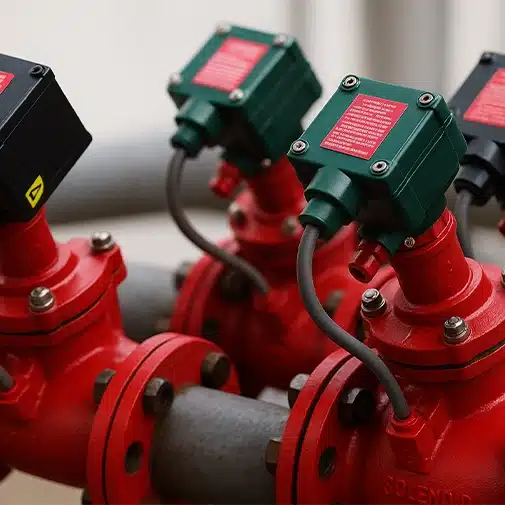

Solenoid valve is a component used in industrial automation and control systems that operates with electrical energy. This component is designed to manage the flow of liquids or gases. Its general purpose is to start, stop, or redirect the flow in piping systems.

Solenoid valve operate based on the principle of electromagnetism and provide reliability and precision in the applications they are used in. These components, which are widely used in various areas, have advanced models that operate integrated with digital control systems. This ensures energy savings and minimizes human intervention.

What is a Solenoid Valve?

It is a component designed to manage the flow of liquids and gases. This component operates with electrical energy and is used in piping systems to start, stop, or redirect the flow.

Solenoid valves operate on the principle of electromagnetism and create a magnetic field by applying electric current to the coil. This magnetic field moves the piston inside the valve, thereby controlling the flow.

The general features of a solenoid valve are as follows:

These components, which are used in many areas, also have many advantages. One of the most prominent advantages is that they provide automation and efficiency. They work automatically without the need for manual intervention and save labor.

They automatically regulate the flow rate of liquids or gases and have precise control features.

The component’s energy consumption is very low, which lays the groundwork for energy savings.

It has a fast response time and offers features such as safe shutdown. It can also be easily integrated with other automation systems.

The component has a wide range of applications and can be used in different industries and systems. Additionally, they are made from durable materials, which provides the advantage of long-term use.

What is the Function of a Solenoid Valve?

Solenoid valves have applications in different areas and perform certain functions in these fields. These functions are as follows:

- Flow control: The components regulate the flow of liquids and gases.

- Automation: They operate as part of automatic systems, reducing the need for manual control.

- Safety: With their features, they make the transfer of hazardous chemicals safe.

- Efficiency: They save energy, which supports increased system efficiency.

This component is used in many different areas and plays an important role, especially in industrial and commercial fields.

In industrial production, it controls the flow of liquids and gases in chemical processes. At the same time, it regulates flow in automation systems.

In the automotive sector, the LPG solenoid valve securely manages gas flow in vehicles.

It performs automatic water control in agriculture and irrigation applications.

It is used in water heaters, boilers, and faucet systems and is also suitable for domestic use.

It is preferred in devices that require precise flow control. Examples of these devices include medical and laboratory systems.

Its use is preferred in safety systems. The burst solenoid valve is used to quickly stop the flow in emergencies.

Solenoid valves stand out with their usage in modern industries and daily life. These valves, with their features, advantages, and variety of applications, are indispensable components in both small-scale projects and large industrial projects.

Working Principle of Solenoid Valves

Solenoid valves operate using the electromagnetic method and consist of solenoid valve parts such as coils, pistons, and spring mechanisms.

The coil creates a magnetic field when electric current is applied. The magnetic field generated moves the piston, slowing down or stopping the flow. Through spring mechanisms, the piston is returned to its original position when the electricity is cut off.

They are of great importance in industrial processes by offering fast response times and precise flow control.

These components work with automatic valve systems, providing energy savings as well as offering usage advantages.

“Where are solenoid valves found?” Solenoid valves can be found in industrial facilities, automation systems, irrigation systems, and vehicles.

Solenoid Valve Prices

Solenoid valve prices vary depending on various factors. Factors affecting prices include the technical specifications of the valve, manufacturing materials, brand, and intended use.

One of the factors directly influencing prices is the valve type and working mechanism. Another factor directly affecting prices is the quality of materials. Brass, one of the commonly used materials, is an economical option. Stainless steel, which has high chemical resistance, is more expensive than other materials.

Size and connection diameter, pressure and temperature resistance, and brand are also directly influential on prices. For example, high-performance and long-lasting products from well-known brands such as Asco Solenoid Valves generally have higher prices.

The types of solenoid valves also affect prices. These valves are designed to meet different needs.

Normally closed valves stop the flow when there is no electricity.

Normally open valves allow the flow to continue when there is no electricity.

The LPG solenoid valve is a type that effectively manages gas flow in vehicles.

The pressure-operated valve is generally preferred in high-pressure systems.

The burst solenoid valve type is specially designed for safety systems.

Another factor affecting prices is additional features and certifications. Models that can be controlled remotely or integrated into automation systems may have higher prices.

Selecting the right model suitable for the application area and needs allows for a balance between cost and performance.

For more detailed information about solenoid valve types, features, and application areas, you can contact Mega Industry.