Tank automation refers to systems used in the fuel industry to manage the filling, stock, and shipment processes of storage tanks. Tank automation operates automatically, ensuring the safe and efficient management of fuel.

Tank automation systems have the primary feature of reducing manual errors, which helps improve operational efficiency. This also contributes to lowering operational costs. These systems are frequently used in petrol stations and storage facilities.

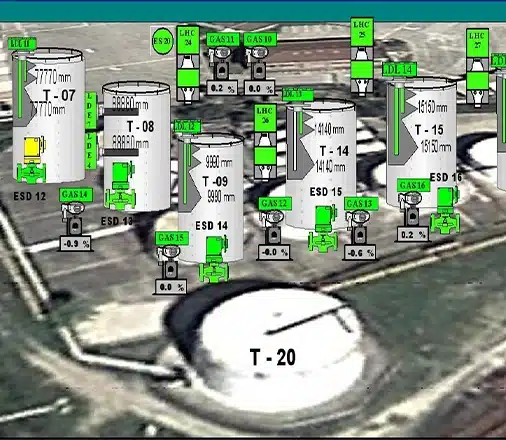

Tank Automation System

A tank automation system is commonly implemented in petrol stations or storage facilities to ensure the safe and efficient management of fuel. The system offers several key features:

- Real-Time Monitoring and Control: The system automatically monitors tank levels, temperature, and pressure. This capability helps detect and prevent potential risks in advance.

- Inventory Management: It facilitates the automatic recording of stock levels and consumption data, ensuring accurate and continuous supply management.

- Safety and Risk Management: The system includes preventive measures against overfilling, leaks, or explosion risks. Alerts are automatically sent to operators and managers in case of risky situations.

- Automated Reporting and Analysis: Detailed reports of processes like tank filling and discharging are provided. This allows businesses to evaluate and optimize their performance through analysis.

These systems, which aim to minimize human error, are highly preferred by businesses due to their operational advantages.

The prices of tank automation systems vary based on different sectors and operational needs. The main factors influencing pricing include:

- System scope and features

- Number and capacity of tanks

- Technology used

- Integration requirements

When selecting a tank automation system, businesses should consider their needs and budget, evaluating aspects such as installation, costs, and maintenance.

Advantages of Tank Automation Systems

Tank automation systems enable businesses to conduct safer, more efficient, and cost-effective operations, making them indispensable in modern fuel management.

By minimizing manual processes and speeding up filling and shipment operations, these systems help reduce labor costs and save time. They also optimize energy consumption.

Advanced safety features automatically prevent risks like overfilling, leaks, or explosions, thereby enhancing the safety of both employees and the facility.

Tank movements and stock records are accurately maintained, ensuring full compliance with regulatory inspections and reporting requirements.

The system allows centralized control of tanks at different locations through remote data access.

Fuel Tank Automation

Fuel tank automation is a system frequently used in petrol stations and storage facilities to manage fuel effectively. It ensures continuous monitoring of tanks and automates the filling process.

Areas of use are fuel filling facilities, gas stations, and industrial facilities.

Key advantages filling operations are carried out with minimal human intervention, enhancing safety and efficiency. By preventing manual errors, this system helps optimize operational processes, reducing costs. Tank levels and movements are accurately recorded, ensuring compliance during audits. This system has become an essential technology for modern operations, providing secure, efficient, and cost-effective solutions.

This system is one of the indispensable technologies for operations today, offering not only improved business processes but also safe, efficient, and cost-effective solutions.

Importance of Fuel Tank Automation

The fuel tank automation system is a technology used in modern facilities to optimize operational processes, ensuring the safe and efficient storage and management of fuel.

This system offers numerous advantages to businesses, with its primary importance being the ability to provide real-time monitoring and control. By enhancing operational efficiency, these systems automate fuel filling and discharging processes, saving both time and labor.

With its safety and risk management features, the system is critically important for ensuring the security of both employees and the facility.

Additionally, the system’s ability to provide energy and cost savings, as well as its compatibility with remote monitoring and management, makes it a highly valuable tool for businesses. It is also an indispensable technology for companies in the fuel industry aiming to gain a competitive edge.

For more detailed information about tank automation systems and their features, you can contact Mega Industry.